Wake Forest has received the first patent for a new solar-cell technology that can double the energy production of today’s flat cells at a fraction of the cost.

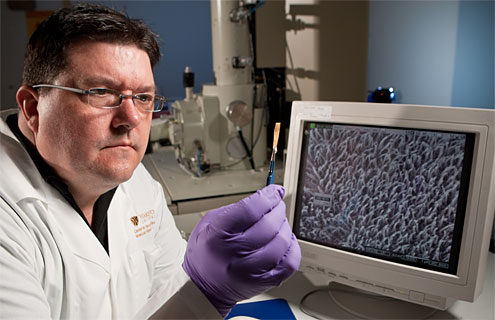

“It comes at a pretty high price to be green,” said David Carroll, the director of Wake Forest’s Center for Nanotechnology and Molecular Materials, where the fiber cell was developed. “This device can make a huge difference.”

The University received the patent for fiber-based photovoltaic, or solar, cells from the European Patent Office; applications to the U.S. Patent Office are pending.

The patent on the technology has been licensed to FiberCell Inc. to develop a way to manufacture the cells. The company, based in the Piedmont Triad Research Park in downtown Winston-Salem, is producing its first large test cells.

The new solar cells are made from millions of minuscule plastic fibers that can collect sunlight at oblique angles – even when the sun is rising and setting. Flat-cell technology captures light primarily when the sun is directly above.

Where a flat cell loses energy when the sun’s rays bounce off its shiny surface, the fiber-based design creates more surface area to confine the sun’s rays, trapping the light in the tiny fiber “cans” where it bounces around until it is absorbed almost completely. That means much greater energy production with fiber-based cells: the new fiber cells could produce about twice as many kilowatt hours per day as standard flat cells.

“We’ve been able to show that with a standard absorber we can collect more of the photons than anyone else can,” Carroll said. “Because of the way the device works, I get more power.”

To make the cells, the plastic fibers are assembled onto plastic sheets, with a technology similar to that used to create the tops of soft-drink cups. The absorber – either a polymer or a dye – is sprayed on. The plastic makes the cells lightweight and flexible – a manufacturer could roll them up and ship them anywhere cheaply.

Carroll envisions several key uses for fiber cells:

- Green building: “We’ve known how to build the ‘smart house,’ it’s just been too expensive,” he said. “The fiber cell can change that.” Alter the dimensions and dye color, and builders can integrate the cells nearly anywhere in the home’s design. Because fiber cells can collect light at various angles, they no longer have to stay on the roof to work. Partner the cells with devices that could store the power more efficiently, turn off lights and appliances when not in use, and capture and redirect the heat the building radiates at night, and you have a more affordable, energy-efficient structure.

- Bringing power to developing countries: Once the primary manufacturer ships the lightweight, plastic fiber cells, satellite plants in poor countries can spray them with the dye and prepare them for installation. Carroll estimates it would cost about $5 million to set up a finishing plant – about $15 million less than it would cost to set up a similar plant for flat cells.

- Revolutionizing the power grid: “What if you didn’t own your roof,” Carroll asked. “What if the power company did?” The fiber cells installed on some homes in each neighborhood would feed the grid, and the power company would monitor energy collection and distribution through a computer network. The homeowner would not maintain the cells; that responsibility would fall to the power company.

Categories: Research

Headlines

Wake Forest in the News

Wake Forest regularly appears in media outlets around the world.