Say goodbye to that annoying buzz created by overhead fluorescent light bulbs in your office or residence hall. Wake Forest scientists have developed a flicker-free, shatterproof alternative for large-scale lighting.

The lighting, based on field-induced polymer electroluminescent (FIPEL) technology, also gives off soft, white light – not the yellowish glint from fluorescents or bluish tinge from LEDs.

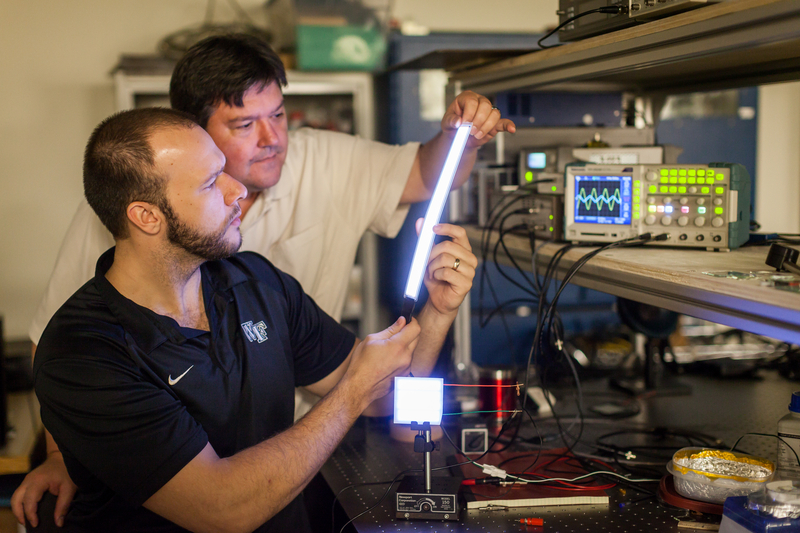

“People often complain that fluorescent lights bother their eyes, and the hum from the fluorescent tubes irritates anyone sitting at a desk underneath them,” said David Carroll, professor of physics and director of the Center for Nanotechnology and Molecular Materials. “The new lights we have created can cure both of those problems and more.”

The team uses a nano-engineered polymer matrix to convert the charge into light. The technology allows the researchers to create an entirely new light bulb – overcoming one of the major barriers in using plastic lights in commercial buildings and homes.

The research supporting the technology is described in a study appearing online in advance of publication in the peer-reviewed journal Organic Electronics.

Graduate student Greg Smith has worked on this project for about two years, first developing a system to test the efficiency of the device.

“There is something very rewarding about building a device and seeing it light up for the first time using a system you helped develop,” he said. “I really enjoy working on such a revolutionary project. Professor Carroll has an uncanny ability to pursue new technologies and engage students in these projects. The ultimate reward for me would be to walk into a building and seeing a lighting panel using technology that I helped develop.”

The device is made of three layers of moldable white-emitting polymer blended with a small amount of nanomaterials that glow when stimulated to create bright and perfectly white light similar to the sunlight human eyes prefer. However, it can be made in any color and any shape – from 2×4-foot sheets to replace office lighting to a bulb with Edison sockets to fit household lamps and light fixtures.

This new lighting solution is at least twice as efficient as compact fluorescent (CFL) bulbs and on par with LEDs, but these bulbs won’t shatter and contaminate a home like CFLs or emit a bluish light like LED counterparts.

“If you wanted blue lights, discos would still be popular. You want lights that have a spectral content that is appealing to us inside of a building,” Carroll said. “You want a light that won’t shatter and create a hazmat situation while your children are around.”

Carroll’s group is the first to make a large-scale FIPEL that can replace current office lighting and is based on natural white light. Beyond office and home lighting, Carroll sees potential uses for large display lighting, from store marquees to signs on busses and subway cars.

FIPELs also are long-lasting; Carroll has one that has worked for about a decade.

Wake Forest is working with a company to manufacture the technology and plans to have it ready for consumers in the next year.

Categories: 2012 Highlights: Science and Research, Faculty, For Alumni, For Parents, Research, Student, Top Stories

Headlines

Wake Forest in the News

Wake Forest regularly appears in media outlets around the world.